Best Practices for Running a Fuel-Efficient Program

Fuel efficiency is almost always top of mind for fleet managers, where minimizing fuel costs by focusing on safety and sustainability among drivers is paramount. Apart from driver behavior, there are other factors that affect fuel consumption. Below, we outline some best practices fleet managers can lean on to help them run more fuel-efficient fleets:

Select the right type of vehicle prior to signing a lease

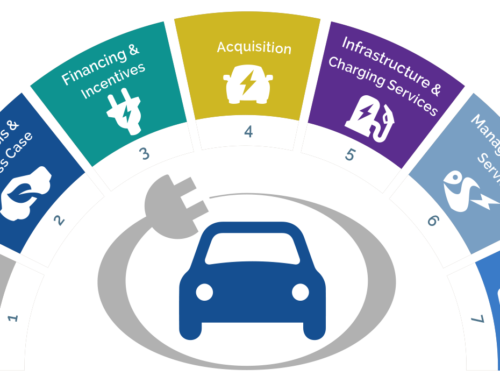

Vehicle selection impacts everything from fuel cost to driver safety, so before you decide to sign a lease, take the time to ensure you’ve made a choice that aligns with your strategies. We’ve previously identified a process to help fleet managers clearly identify the right type of vehicle for their fleet—and this is still relevant today.

- Define operating specs: Once you determine how your drivers will use the vehicles, things like locations and distances traveled by your drivers are also important to keep in mind before deciding on the type of vehicle you need. For example, on-road vs. off-road locations both result in different fuel-efficiencies, so do the road conditions and the frequency and distance traveled by drivers. By knowing these things in advance, selecting the right vehicle becomes a lot easier.

- Driver well-being: It’s also important that you prioritize your drivers’ comfort by selecting vehicles that come equipped with safety features—so be sure to select accordingly.

- Establish fleet size: The size of your fleet is also important in helping determine the right type of vehicle for your fleet

- Set a timeline: It’s important to consider when you’ll actually need the vehicles and to plan accordingly.

- Weigh costs: In the end, selecting the right vehicle, carefully considering operating specs, prioritizing driver well-being, and determining fleet size all contribute to long-term savings—so it’s important that you weigh your options carefully to help the right choices.

Determine the type of cargo—including elements like weight, distribution and type

Apart from determining vehicle use, the type of vehicle also plays a role in fuel efficiency. A small, lightweight car, for example, will have much better fuel efficiency when compared to a truck or SUV. However, if a small vehicle is headed to a construction site, where extra tools and supplies will potentially be taken along, the extra pounds will raise fuel costs because the small vehicle requires more effort to transport the extra weight. So, determining the type of cargo and planning vehicle selection accordingly is key to lowering fuel costs and maximizing efficiency.

Extend your fleet replacement cycle to decrease costs

In addition to selecting the right vehicle and determining the type of cargo your vehicle will transport, avoiding the trap of irregular replacement cycles is key. Otherwise, not only is the potential resale value of the vehicle affected, but the maintenance cost increases, affecting overall fuel economy. To avoid this, some companies choose to extend their fleet management cycles, a solution to reduce the company’s spending.

Different companies have varying replacement cycles, depending on their fleet utilization, but extending the fleet replacement cycle is a first step to decreasing costs. If you are considering extending your replacement cycle due to budget concerns, a fleet renewal plan that is prepared by a fleet management company will help you run a more fuel-efficient fleet. This will not only lead to better results in the long run, but will also contribute to better gas mileage, less pollution, and less employee downtime.